Multi-pore Particle Synthesis Technology

Graphical representations and technical data illustrate the multi-pore particle synthesis technology developed by Tosoh scientists. The characteristics of the technology are shown below.

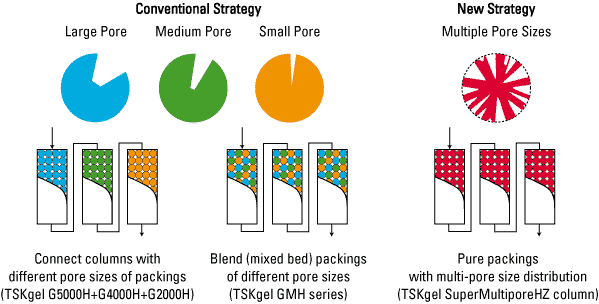

Strategies to Expand Linear Calibration Curves in Size Exclusion Chromatography

|

|

The scanning electron micrographs in Figure 2 demonstrate the monodispersity of the particle size distribution, while Figure 3 shows that the pore volume of TSKgel SuperMultiporeHZ particles is distributed over a wide range of pore sizes. The main benefit of multi-pore technology, a smooth chromatogram without inflection points, is shown in the chromatogram in Figure 4.

|

In general, columns with an extended linear calibration range can be constructed in one of three ways.

|

|

The simplest way to obtain an extended linear calibration range is to couple columns, each containing particles with distinct pore size distributions. It is inevitable that the resulting calibration curve will deviate from linearity between each pore size range, resulting in irregularities in the chromatogram.

|

|

The irregularities in chromatograms occur less frequently in the case of mixed-bed columns. Mixed-bed columns are prepared by mixing batches of particles each containing a narrow pore size distribution. However, inflection points in chromatograms can still arise due to a mismatch of pore sizes.

|

|

Such inflection points are no longer observed with columns packed from particles prepared by multi-pore technology, as shown below in Figure 4.

|