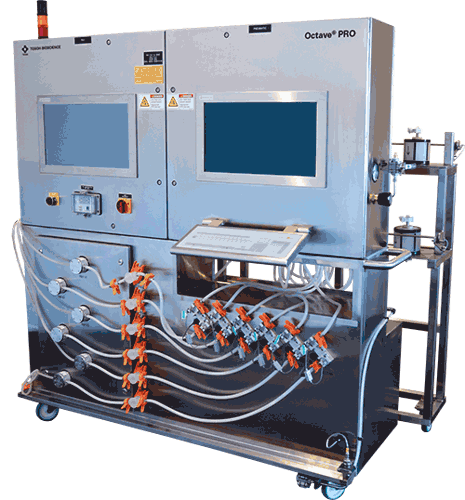

OctaveTM PRO MCC System

The Octave PRO is a GMP-ready multi-column chromatography (MCC) system for the purification of biopharmaceuticals at the clinical and commercial scale. The Octave PRO is designed for direct scale-up after process development on the Octave BIO, and both systems offer the same method-execution capabilities. The Octave PRO enables ultimate process versatility and agility to address the most challenging downstream bottlenecks.

| GMP-ready using reliable, patented Octave technology |

Specifically designed for typical clinical and commercial scale purification processes of 2000 L bioreactors

within 1-2 shift times |

| Flow rates ranging from 0.1 L/min to 2.5 L/min |

| Up to eight columns |

| Six pumps, six inlets, six outlets |

| Single use flow path |

| Integrated UV, conductivity, and pH sensors (4 of each) |

| Complete data recording and analysis |

| Includes ProComposer™ Method Creator and Method Wizard applications |

| 21 CFR Part 11 compliant PROController™ control system |

| Dedicated SkillPak PRO pre-packed columns for MCC applications are available |

Ordering Information

Please inquire [email protected] »

| 0041201 |

Octave PRO EU, Octave PRO GMP ready multi-column chromatography skid for EU region |

| 0041202 |

Octave PRO SU Flowkit, Full single-use flowkit for the Octave PRO |