Introduction to the Multi-Column technique

MCC can be run continuously and intensifies the chromatography step, compared to batch chromatography.

Compared to an injection of a distinct sample volume onto a comparably large column as done in classic batch- or single-column chromatography, MCC takes significant advantage of spreading the sample load across multiple columns in a cyclical process. As a result, a several-fold increase in productivity is typically achieved with resin, buffer, and time savings.

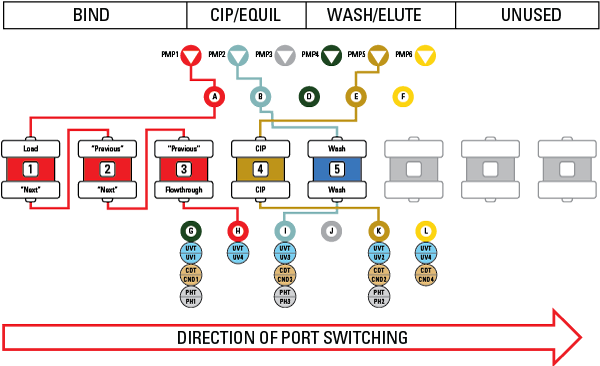

The OctaveTM systems are comprised of a set of pumps that continuously load solutions onto the system and valve manifolds that connect the pumps to the columns. The columns are connected to each other through a pressurized valve block that allows each valve to be independently actuated so any given buffer can flow through any given column(s) and outlet. The column outlets are connected to a set of four integrated UV, conductivity, and pH sensors and a peak collection valve.

In the figure below, a typical MCC method for purification is shown. For this MCC process, three of five columns are connected in series via the valve block, enabling increased loading amounts and higher resin utilization, since product breakthrough is caught on subsequent columns. While these three columns are in the Load phase, the remaining two columns go through the Wash, Elute, CIP, and Equilibration phases. Once the first column in the loading series is fully loaded, the valve block redirects the flow path so the columns “rotate” against the flow current. The first column starts the Wash phase, and the second column is now in the Load phase. An MCC run usually consists of four to six cycles, in which columns are rotated though the different process steps. In the last cycle, the feed is replaced by buffer to initiate the end of the run and re-establish initial conditions.