56

AFC

TOYOPEARL Resins for Protein A Affinity Chroma-

tography

Protein A affinity chromatography is the most commonly

used capture step in antibody purification processes. Its

high specificity for the binding of human immunoglobulin

allows highly selective capturing of the target protein out

of cell culture supernatant. The protein A capture step is

most often followed by ion exchange, HIC or mixed-mode

polishing steps in order to remove nucleic acids, aggre-

gates and leached protein A.

The first protein A affinity resins were introduced in the

1970s based on native protein A ligands derived from the

bacterium Staphylococcus aureus. These media suffered

from insufficient alkaline stability, which limited the

cleaning in place options for process use. State-of-the-art

protein A resins carry recombinant protein A variants

genetically engineered to provide maximum IgG affinity

and base stability.

Tosoh Bioscience offers two protein A affinity resins, both

based on alkaline stable, recombinant ligands coupled to

the proven TOYOPEARL polymethacrylate matrix. The new

ultra-high capacity TOYOPEARL AF-rProtein A HC-650M

excels all other commercially available protein A media

with regard to its IgG binding capacity.

Protein A Chromatography – How does it work

Protein A is a 40-60 kDa surface protein originally found in

the cell wall of the bacteria Staphylococcus aureus. Protein

A and its recombinant derivatives bind the Fc region of

immunoglobulins through interaction with the heavy chain.

The binding strength of protein A for IgG depends on

the source species of the immunoglobulin as well as the

subclass of IgG. The standard protocol for antibody purifi-

cation by protein A chromatography involves loading of the

feedstock at physiological pH and ionic strength, washing

unbound substances of the column with loading buffer and

elution of the bound immunoglobulins by lowering the pH.

The change in pH alters the degree of ionization of charged

groups on the ligand and the bound antibody thus reducing

the affinity. The fractions can be collected into neutraliza-

tion buffer to return to a neutral pH.

TOYOPEARL Protein A RESINS

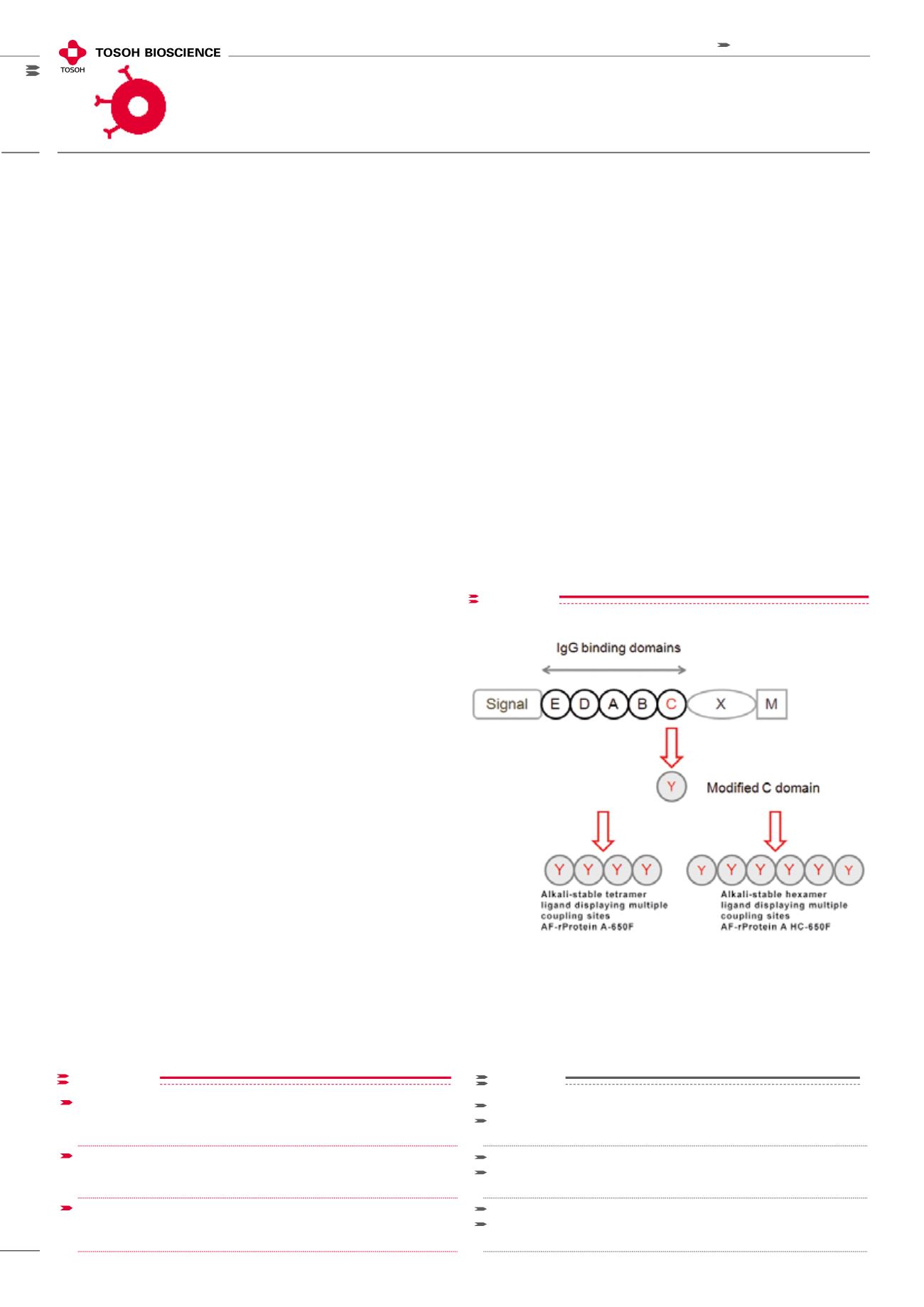

The ligands of all TOYOPEARL protein A resins are recombi-

nant protein A variants expressed in E. coli. They are derived

from one of the IgG binding domains of protein A. The

amino acid sequence is optimized in order to increase the

protein’s stability towards alkaline solutions and to intro-

duce additional lysine residues that can be utilized for multi-

point attachment of the ligand to the TOYOPEARL matrix.

The ligand of TOYOPEARL AF-rProtein A-650F consists of

a tetramer of these modified protein A C domains. For the

ultra-high capacity TOYOPEARL AF-rProtein A HC-650F this

domain was further optimized and expressed as a hexamer

in order to further increase IgG binding capacity (Figure 1).

Multipoint attachment of the ligand to the TOYOPEARL

matrix enhances the chemical and thermal stability of the

resin. In practice this pays off for a low level of protein A

leaching and also for a high resistance to alkaline solutions.

Both resins are based on the TOYOPEARL HW-65F base

bead with a particle size of 45 μm.

Protein a Affinity

chromatography

features

Benefits

High IgG binding capacity

Increased productivity of antibody purification

Lower buffer consumption

Recombinant protein A ligand

Alkaline stable

Low protein A leakage

TOYOPEARL polymer matrix

High mechanical stability

High chemical stability

figure 1

RECOMBINANT PROTEIN A DERIVED LIGANDS