TOSOH

CUSTOMER MAGAZINE

Heat treatment has been applied for decades to prevent bacterial growth

in the beverage and food industry. Static and dynamic binding capacity of

TOYOPEARL AF-rProtein A-650F and TOYOPEARL AF-rProtein A HC-650F

is not affected by 30 minutes wet incubation at 90 °C. The host cell protein

removal of these resins after thermo-treatment is similar.

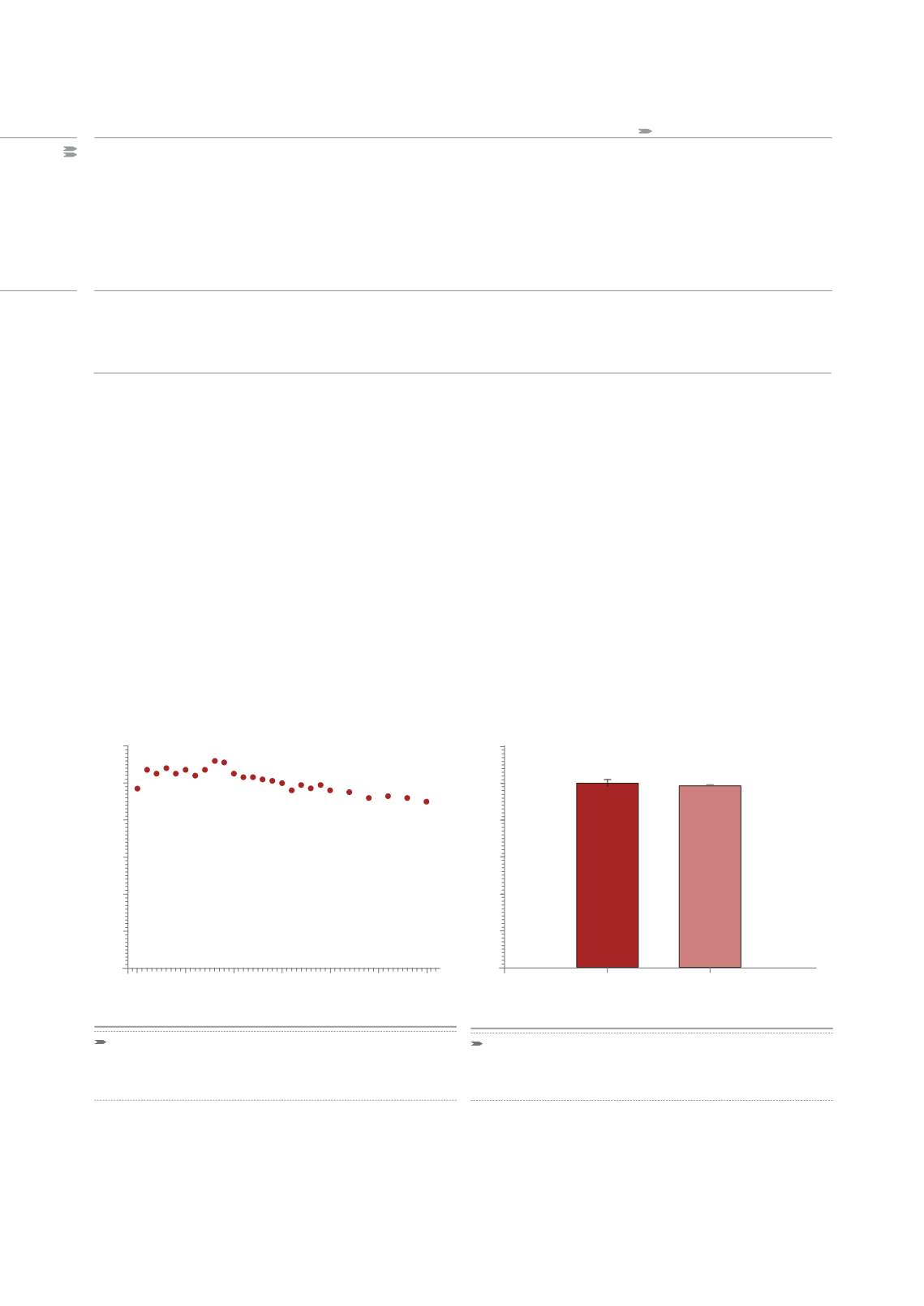

The success story of protein A chromatography as a capturing step in mAb

production has been pushed by the introduction of alkaline stable protein

A ligands. The TOYOPEARL Protein A resin family has two alkaline sta-

ble members, namely TOYOPEARL AF-rProtein A-650F and TOYOPEARL

AF-rProtein A HC-650F, ‘HC’ standing for high capacity. 80 % of the dy-

namic binding capacity (DBC) of TOYOPEARL AF-rProtein A HC-650F is

preserved after 300 cycles of treatment with 0.2 M sodium hydroxide at a

contact time of 15 minutes (Figure 1).

Alternative agents or treatments frequently applied in the biopharmaceuti-

cal industry include chaotropic agents, such as guanidinium hydrochloride

or urea. However, other industry sectors, such as the food and beverage

industry sector face similar challenges with regards to bacterial contami-

nation. Wet heat treatment is one approach that is applied for the saniti-

zation of bottling plants. Wet heat treatment at 77 °C (170 °F) for at least

15 minutes or at 93 °C (200 °F) for at least 5 minutes is recommended

by the authorities [1]. Thermal sanitization can also be applied in biophar-

maceutical production. Tanks and other installations that hold water for

injection (WFI) require sanitization, as well. According to the US Pharma-

copeia, “temperatures of at least 80 °C are most commonly used for this

purpose” [2]. The World Health Organization recommends in its Specifica-

tions for Pharmaceutical Preparations periodical sanitization of water dis-

tribution pipework with temperatures exceeding 70 °C to inhibit growth of

microorganisms [3]. Thus, use of thermal sanitization for chromatography

resins seems a promising alternative to chemical sanitization.

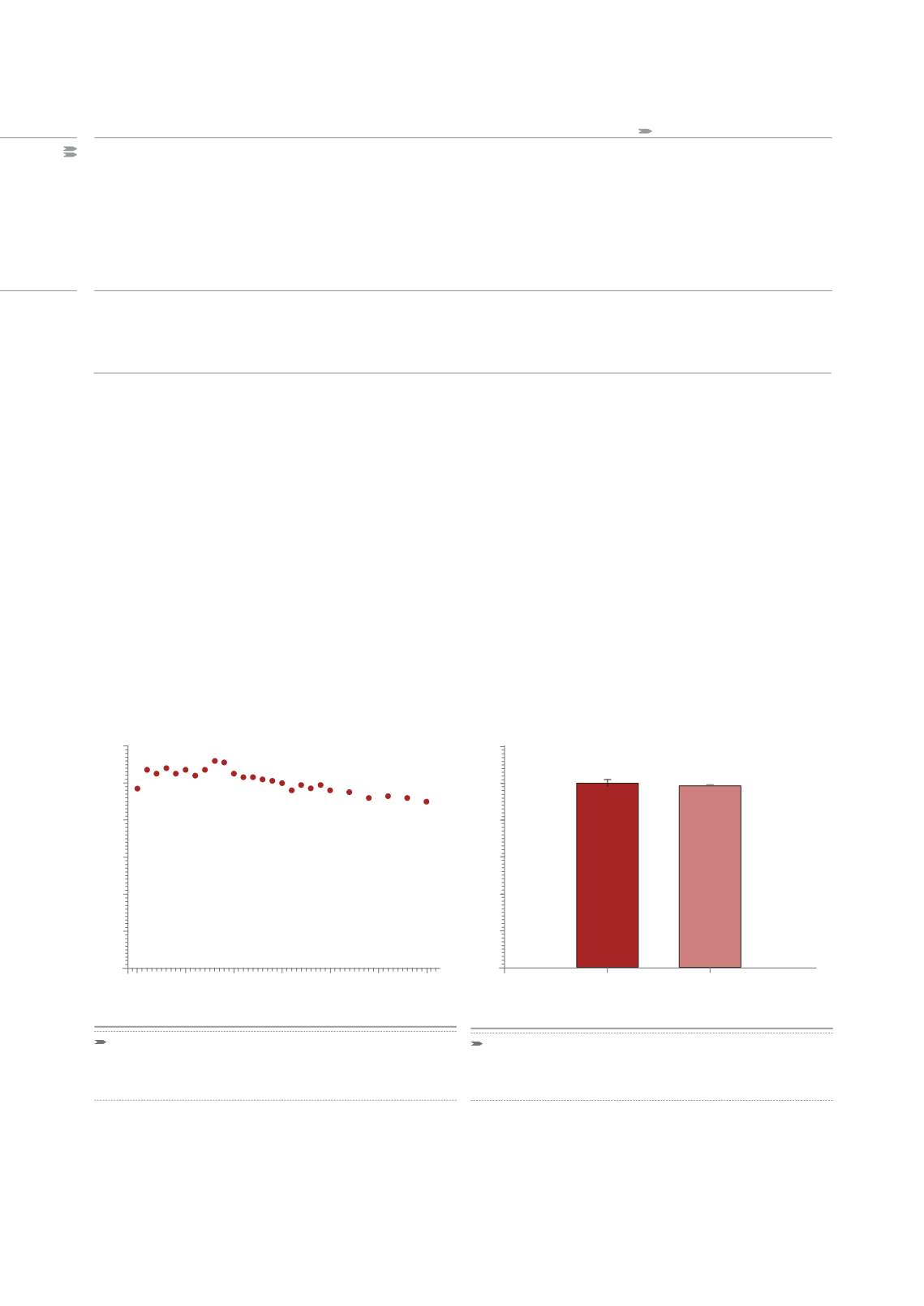

TOYOPEARL AF-rProtein A HC-650F has been incubated in aqueous so-

lution at 90 °C for 30 minutes. The thermo-treated resin has been used in

static binding capacity experiments. No significant change in static binding

capacity can be observed (Figure 2).

THERMO-SANITIZATION OF PROTEIN A

CHROMATOGRAPHY RESINS

PROTEIN A CHROMATOGRAPHY IS A WIDELY APPLIED PURIFICATION PLATFORM FOR CAPTURING OF MONOCLONAL ANTIBODIES.

COMMON CLEANING IN PLACE STRATEGIES OFTEN INVOLVE SODIUM HYDROXIDE TREATMENT OF THE RESIN. STABILITY OF NATURAL

PROTEIN A LIGANDS AGAINST SODIUM HYDROXIDE IS LOWER COMPARED TO LIGANDS USED IN HYDROPHOBIC INTERACTION OR ION

EXCHANGE CHROMATOGRAPHY. EVEN THOUGH INTENSE EFFORTS HAVE BEEN INVESTED TO GENERATE ALKALINE STABLE PROTEIN A

LIGANDS, BACTERIAL GROWTH IN PACKED COLUMNS MAY REMAIN AN ISSUE. HEREIN, WE DESCRIBE AN ALTERNATIVE APPROACH FOR

CLEANING IN PLACE, WHICH IS BASED ON HEAT TREATMENT OF THE RESIN.

04

APPLICATION

DOWNSTREAM PROCESSING

FIGURE 2 :

STATIC BINDING CAPACITY OF TOYOPEARL AF-rProtein A HC-

650F AFTER THERMO-TREATMENT AND WITHOUT THERMO-TREATMENT. THE

STATIC BINDING CAPACITY OF THE RESIN FOR mAb IS NOT SIGNIFICANTLY

AFFECTED.

FIGURE 1

DBC OF TOYOPEARL AF-rProtein A HC-650F FOR mAb. THE RESIN WAS

TREATED WITH 0.2 M NaOH AT A CONTACT TIME OF 15 MIN. DBC WAS DETERMINED

WITH A 5 G/L mAb SOLUTION AT 5 MIN RESIDENCE TIME IN 100 mM SODIUM PHOS-

PHATE BUFFER, pH 6.5.

300

250

200

150

100

50

0

no. cycle

40

20

60

120

100

80

0

DBC @ 10% breakthrough

[mg/mL]

AF-rProtein A HC-650F

thermo-treated

AF-rProtein A HC-650F

reference

40

20

60

120

100

80

0

static binding capacity [%]