TOSOH

CUSTOMER MAGAZINE

The dynamic binding capacity (DBC) of a stationary phase is influ-

enced by the contact time between the sample and the ligand, the so-

called residence time. Good mass transfer properties enable a resin

to reach a high binding capacity even at high flow rates. The capacity

of the new resin was tested at various residence times and mAb ti-

ters. Figure 1a & b show the breakthrough curves for TOYOPEARL

AF-rProtein A HC-650F at two feed concentrations. The resin shows

complete mAb adsorption until breakthrough occurs. This remains

unaffected even for short residence times of 1 min. The measured

capacities of more than 100 mg/mL exceed the DBCs of all other base

stable Protein A resins.

To further evaluate the elution properties, a purified humanized mo-

noclonal IgG was diluted to a final concentration of 4.75 g/L. Simula-

ting high HCP density in the feed, aliquots were spiked with concen-

trated cell culture fluid. Protein A chromatography with TOYOPEARL

AF-rProteinA HC-650F was conducted 200 µL RoboColumns using a

robotic chromatography station. The total loaded mass was varied

from 10 to 50 mg/mL resin. A residence time of 2 minutes was ap-

plied. Before elution, the columns were washed with 20 column vo-

lumes of loading buffer.

MAb elution with acetate buffer, pH 3.25 delivered more than 95 %

mAb recovery. Due to the acidic pH applied for elution, mAbs are

prone to aggregation. Naturally, high capacity Protein A resins ad-

sorb large amounts of mAb. This might enhance mAb aggregation

due to higher protein concentrations in the elution pool. Thus, special

attention was paid to the aggregate content after elution of the bound

antibody.

Size exclusion chromatograms of two mAb elution pools are shown

in Figure 2. The elution pools of 10 mg/mL and 50 mg/mL mAb load

were injected, respectively. Although the SEC chromatograms seem

to show aggregates for the higher loading only, a closer look reveals

similar aggregate contents when referring to the corresponding total

protein amount. Both pools contain 0.6 % aggregates.

In biopharmaceutical manufacturing, low Protein A ligand leaching

is crucial and needs to be proved by ELISA testing. Protein A lea-

ching was analyzed for 2.5 g/L and 7 g/L concentrated feed streams.

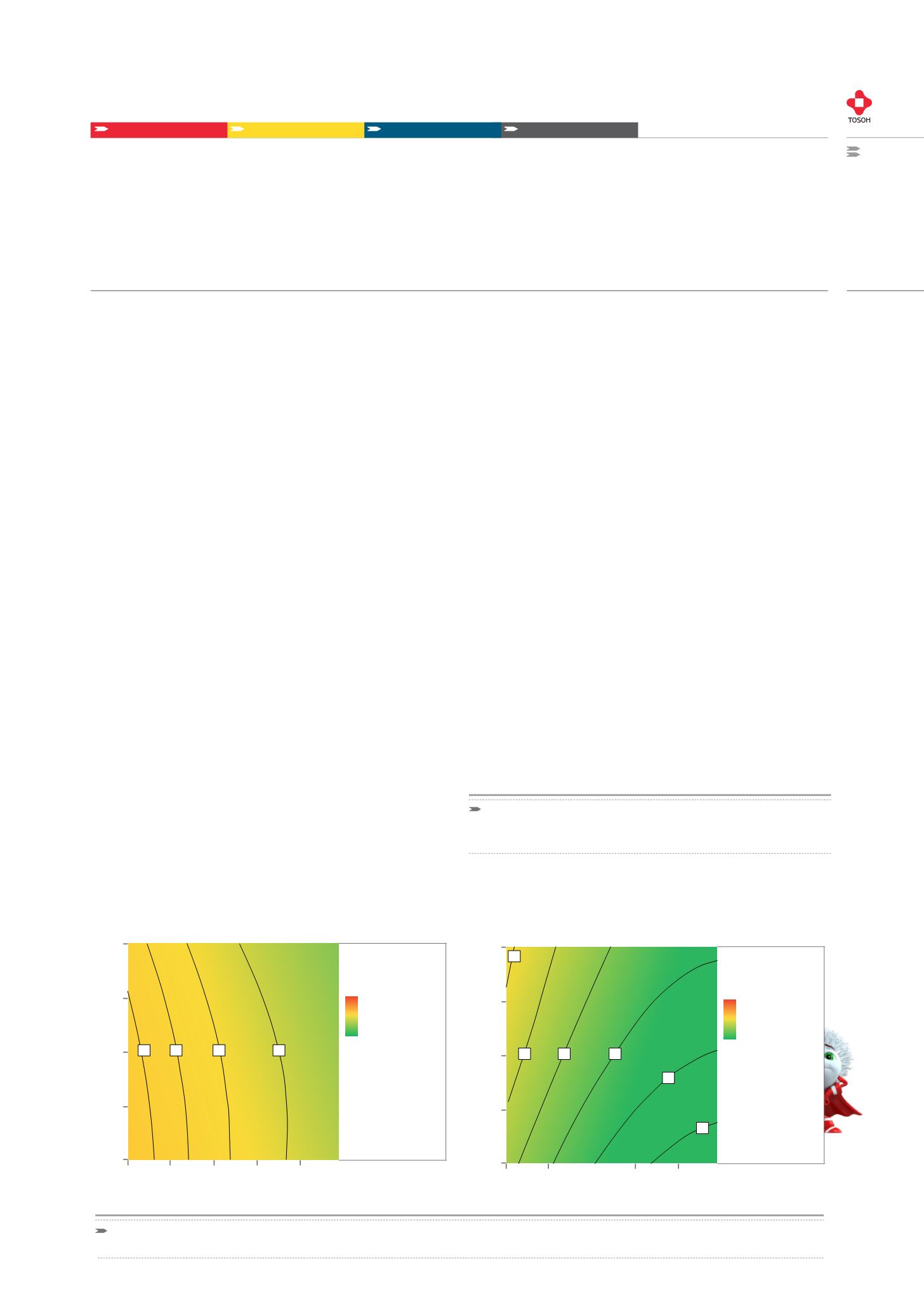

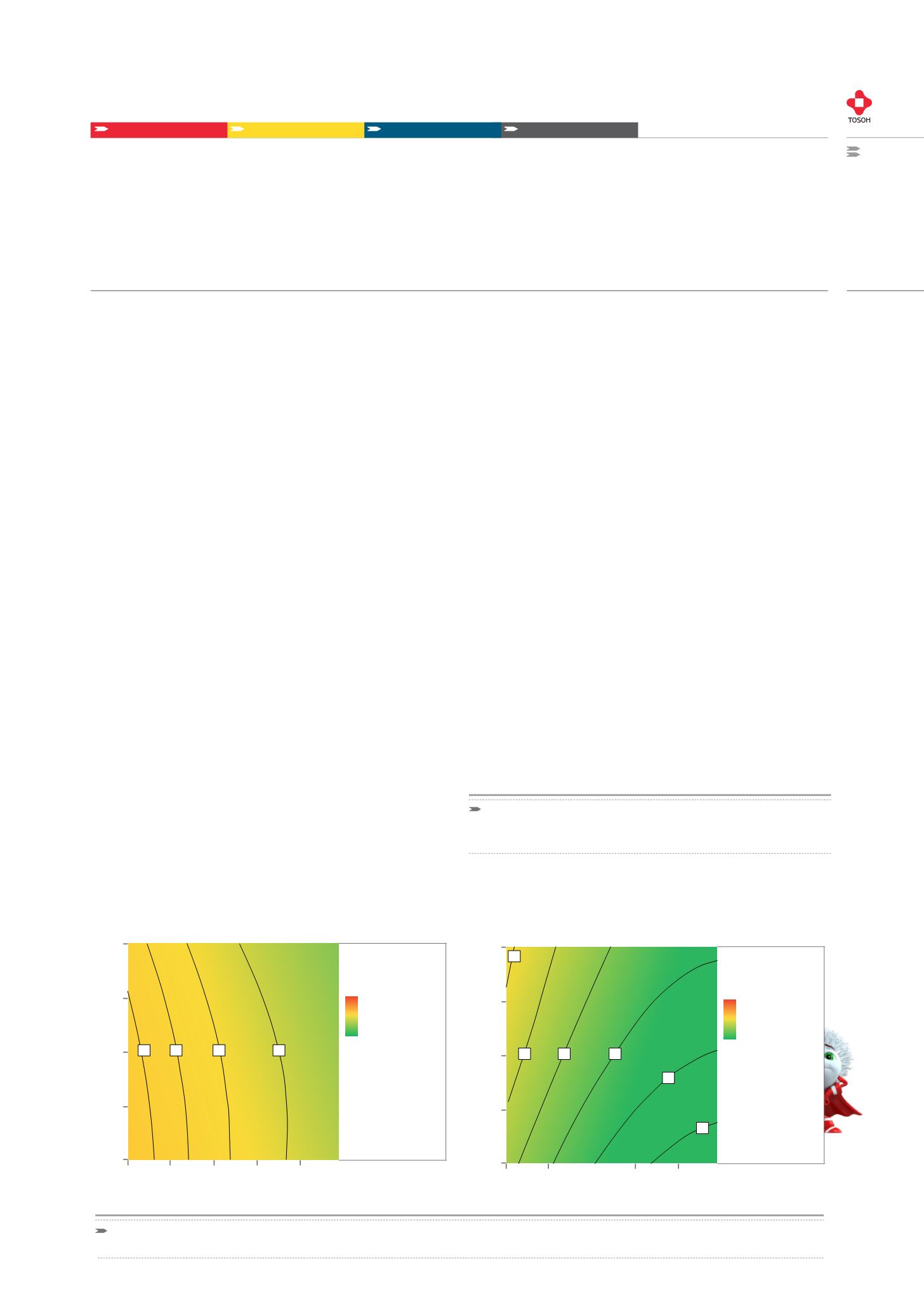

Spiking and residence time were kept constant. Figure 3 shows that

the absolute load has little influence on numeric Protein A leaching.

Overall, Protein A leaching does not exceed 45 ppm for any of the

tested pH and load conditions. Higher absolute mAb loadings seem

to be advantageous, since the relative Protein A content of the mAb

pool decreases.

Considering the obtained results regarding Protein A leaching, ag-

gregate content and protein adsorption, high titers seem favorable

for Protein A chromatography. This mAb seemed unaffected with re-

gards to aggregation, and was efficiently adsorbed, which reduces

Protein A cycle time. Further, Protein A leaching was even lower when

applying higher titers. Thus, ultra-high capacity Protein A resins offer

additional benefits besides reducing costs because less resin volume

is needed to purify a given amount of monoclonal.

AUTHORS

JUDITH VAJDA, TOSOH BIOSCIENCE GmbH, ANGELIKA WACKER, UNIVERSITY OF

APPLIED SCIENCES MANNHEIM

2.75

2.95

3.15

3.35

3.55

elution pH

30.00

25.00

20.00

35.00

40.00

ProteinA leaching (ng/mL)

B: load

Design-Expert®Software

Factor Co

ProteinA leaching

4

5

6

7

X1= A:ph

X2= B:load

Actual Factors

C: titer = 2.50

D: spiking = 15.00

20

0

2.75

2.95

3.15

3.35

3.55

elution pH

30.00

25.00

20.00

35.00

40.00

ProteinA leaching (ng/mL)

B: load

Design-Expert®Software

Factor Co

ProteinA leaching

X1= A:ph

X2= B:load

Actual Factors

C: titer = 7.00

D: spiking = 15.00

20

0

5

3

4

2

1

0

FIGURE 3: PROTEIN A LEACHING

Contour plots for TWO different load concentrations. Protein A leaching is plotted against pH and absolute load. A: 2.5 g/L. B: 7 g/L.