Tosoh

customer magazine

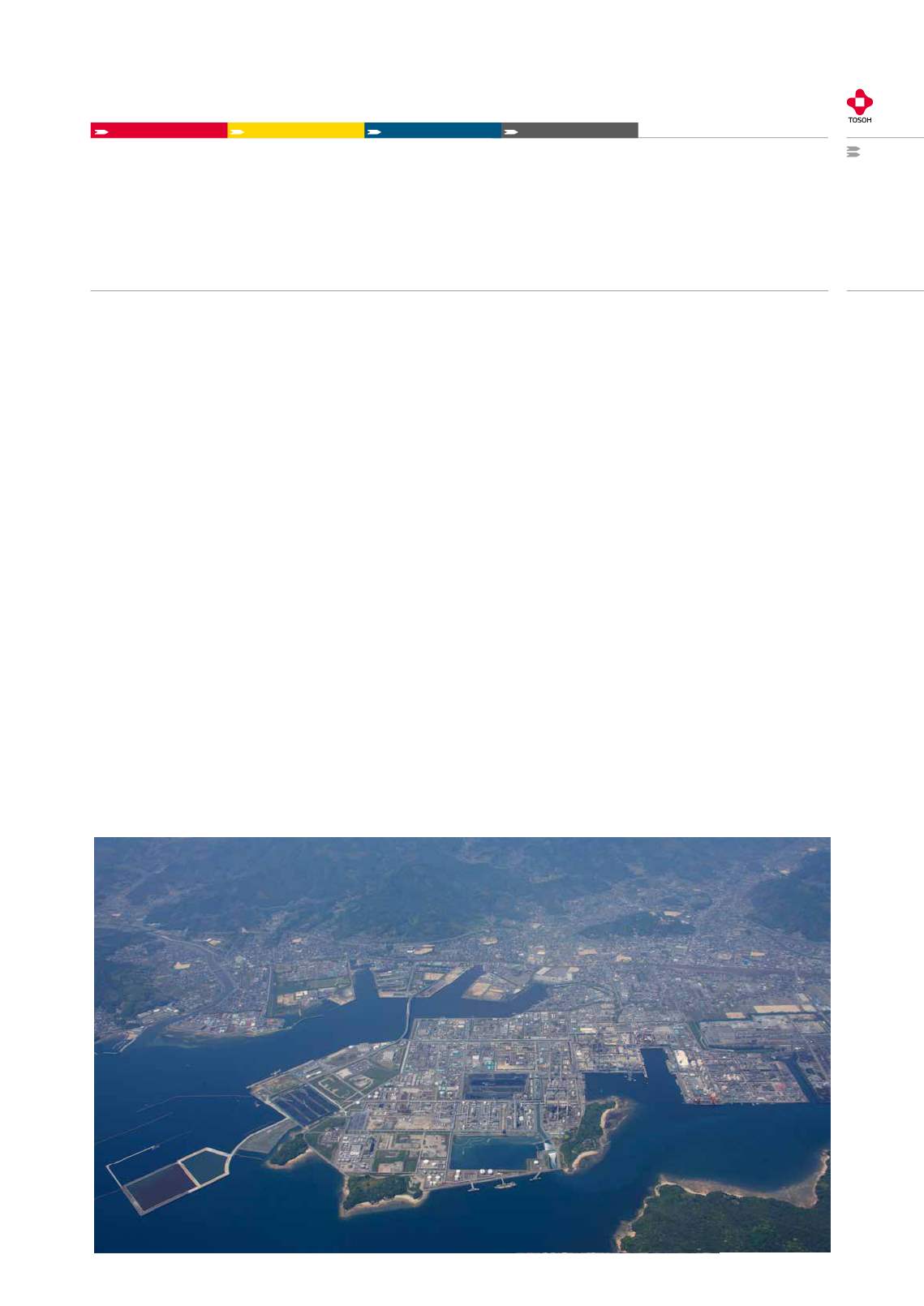

The Nanyo Complex occupies some three million square meters of

land in Yamaguchi, Japan, roughly the equivalent of more than 420

soccer fields. More significantly, it is home to the largest fully integra-

ted manufacturing operations for their class of commodities in Asia,

or what we call the vinyl isocyanate chain. This chain supplies much

of the raw materials, utilities, and infrastructure for the Tosoh Group’s

commodity and specialty products. Input and output along the chain

is managed to optimize cost competitiveness and quality. The result

is a dynamically balanced commodities and specialties strategy that

positions Tosoh for stable profitability and growth.

The Nanyo Complex’s integrated manufacturing operations make To-

soh Japan’s top producer of a variety of commodity chemicals, es-

pecially caustic soda and vinyl chloride monomer, each with a pro-

duction capacity of more than a million metric tons a year. Globally,

high-tech industries ranging from pharmaceuticals and health care

to semiconductors, consumer electronics, and automobiles depend

on Tosoh’s sophisticated products and specialized offerings in high-

value added bioscience, organic chemical, and advanced materials -

principally supplied by the Nanyo Complex. This complex boasts the

world’s largest production capacity for high-purity zirconia powders

and for electrolytic manganese dioxide, which it supplies to about

30% of the global dry cell battery market.

The Nanyo Complex, moreover, is a model of environmental respon-

sibility. Like all Tosoh manufacturing sites in Japan, it has earned ISO

14001 certification for environmental management. It also shares

with Tosoh’s other Japanese manufacturing facilities an adherence to

ISO 9000 series international standards in quality assurance for 100%

of the products it manufactures.

Largely because of the Nanyo Complex’s productivity, Tosoh is a

world leader in high-performance liquid chromatography systems,

analytical columns, and separation media. And Tosoh is construc-

ting plants at the complex to keep pace with demand amid the rapid

growth of other specialty niche markets. Tosoh decided in 2010 to

double its production capacity for its liquid chromatography packing

material TOYOPEARL. In 2012 the new TOYOPEARL plant started pro-

duction for the global market after having passed extensive internal

and external validation procedures. The capacity expansion ensures

that Tosoh can comfortably achieve its immediate goal of supplying

approximately 10% of the global separation media market for biomo-

lecules.

The Separation Center, where the R&D for new product developments

is performed, is located at the Nanyo Complex, too. Latest innovative

products developed there are the ultra-high capacity Protein A resin

TOYOPEARL AF-rProtein A HC-650F, the new generation of mixed-

mode and salt-tolerant ion exchange resins, and UHPLC size exclusi-

on columns for IgG analysis. With the power of the Tosoh R & D work-

force and the Nanyo Complex at our back, we are looking forward to

the next 25 years of successful business in Europe.